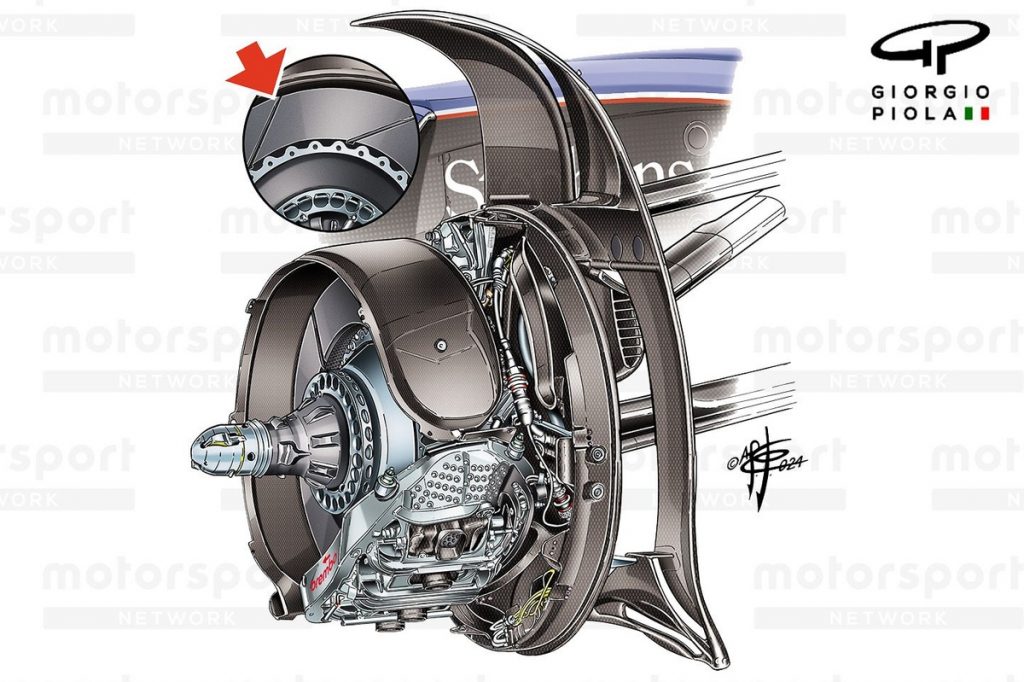

As Formula 1 regulations evolve, teams are constantly exploring innovative ways to revisit and refine concepts that were once abandoned. One such development currently under scrutiny is the reintroduction of grooves on the brake disc rotor. Carbone Industries has been trialling this at recent races, hinting at a potential resurgence of a technology not seen since the era of steel discs.

Williams and Alpine Lead Testing

Williams conducted experiments with the grooved brake discs at the Italian Grand Prix, followed by Alpine at the Mexican Grand Prix. While immediate performance advantages are always the aim, these tests are primarily focused on preparation for the 2025 season. It provides French manufacturer Carbone Industries, which supplies over half the grid, with ample opportunity to refine their designs.

The trials are expected to help teams optimize their braking systems and brake duct designs to complement the new brake disc solutions. Key variables that could impact performance include the number of grooves, their length, shape, and depth.

Adapting to New Wheel Sizes

F1’s shift from 13-inch to 18-inch tyres necessitated a larger brake drum size to fit the revamped wheel wells. Additional regulations prevent the brake drum and wheels from expelling heat and air to avoid undesired aerodynamic advantages. This has prompted novel solutions to direct heat and air, necessary for cooling and managing tyre temperatures.

A prominent design adjustment is the disc fairing, demonstrated with various evolutions since new regulations took effect. Teams have also diversified brake drum designs, constructing layered assemblies to guide air and heat effectively before sealing them to prevent aerodynamic exploitation.

The Impact of Grooved Discs

The reintroduction of grooves is primarily aimed at enhancing the initial ‘bite’ when brakes are applied. This improvement can increase driver comfort and effectiveness, transforming how heat processes through the braking assembly. If these trials prove successful, more teams may implement grooved discs, prompting further alterations in brake assemblies.

Brembo, another key brake supplier, and its partner teams are likely closely observing these advances, exploring potential benefits from grooved disc technology for future seasons.